WARMOTECH PANELS

Warmotech is a recycled PU (polyurethane) foam board, with a density of 550 kg/m3. Warmotech boards can be painted, laminated, combined with other materials to create new products for various applications. It is easily fixed by conventional fixing methods, i.e. using screws or adhesives.

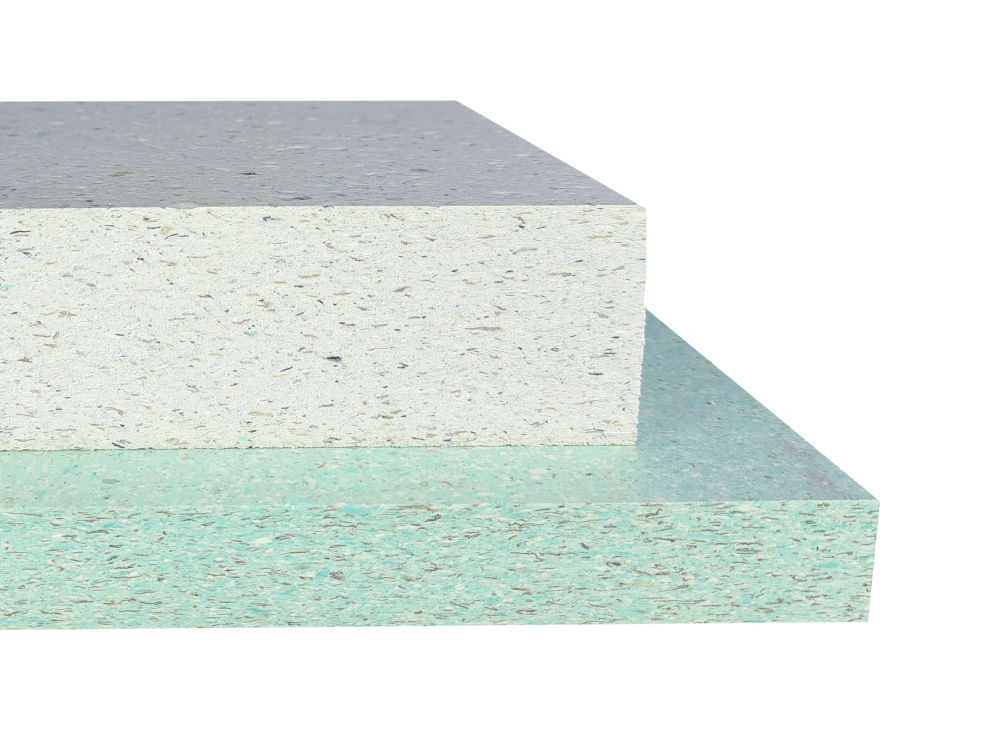

The color of Warmotech boards (green or yellow) depends on the origins of the recycled polyurethane. However, it has no effect on the flammability, mechanical strength, thermal conductivity and other declared characteristics.

Standard panel formats: 1150 x 2750 mm, 1220 x 3020 mm, 1220 x 3600 mm.

Standard panel thickness: 10, 15, 20, 30, 40, 50, 60, 70 mm.

PRODUCT DATA SHEET

| Essential characteristic | Performance and characteristics | Unit | Test method | |

|---|---|---|---|---|

| Reaction to fire | D-s3, d0 | EN 13501 | ||

| Bending strength | ≥ 4,7 | MPa | EN 12089 | |

| Thermal conductivity, λ10 | ≤ 0,088 | W/ (m•K) | EN 12667 | |

| Compressive strength | 10 – 60 mm range | ≥ 7,1 | MPa | EN 826 |

| 61 – 70 mm range | ≥ 6,8 | MPa | ||

| Water absorption (by short term, partial immersion) | ≤ 0,4 | kg/m2 | EN ISO 29767 | |

| Dimensional stability under specified temperature and humidity (DS 70,90) | 1,0 | % | EN 1604 | |

| Dimensional stability under specified temperature and humidity (DS -20,-) | 1,0 | % | EN 1604 | |

| Density | 550 ± 50 | kg/m3 | EN 1602 | |

| Thickness tolerance | not sanded | 0.5 | mm | EN 823 |

| Thickness tolerance | sanded | 0.2 | mm | |

| Length tolerance | 5.0 | mm | EN 822 | |

| Width tolerance | 5.0 | mm | EN 822 | |

| Squareness tolerance | 1.0 | mm/m | EN 824 | |

| Flatness tolerance | 4.0 | mm | EN 825 | |

| Hygroscopic sorption properties1) | ≤ 3,0 | % | EN ISO 12571 | |

| Water vapour diffusion 1) resistance coefficient | 10 – 40 mm range | 60 – 100 | µ | EN 12086 |

| 41 – 70 mm range | 25-60 | µ | ||

| Swelling in thickness, 24h 1) | ≤ 1,0 | % | EN 317 | |

| Moisture content 1) | 2 – 4 | % | EN 322 | |

| Resistance to axial withdrawal of screw | ≥ 650 | N | internal | |

| Water absorption after 24 h in water | ≤ 5,0 | % | internal | |

| Temperature resistance | -50 °C to + 100 °C | |||

| Dimensional change after 24 h in water | ≤ 5,0 | % | internal | |